Durable Triangle Ground Screw Pile

Basic Info

Model No.: HDFT76X800

Product Description

Durable Triangle Ground Screw Pile

Durable Triangle Ground Screw Pile can be installed in the normal ground using ground screw machine or Pile Driver. The package of those durable ground Screw Piles is by steel plate, Any special requirements about triangle ground screw pile, you could tell us and some size of ground screw can be changed. Durable ground screw often is used to kinds of aspects, for example, you plan to build your log cabin in your farm or garden, you could purchase ground screw as the foundation of log cabin or you could purchase the ground screw as the support of garden letterboxes.

| Number | HDFT76*800 |

| Length | 800MM |

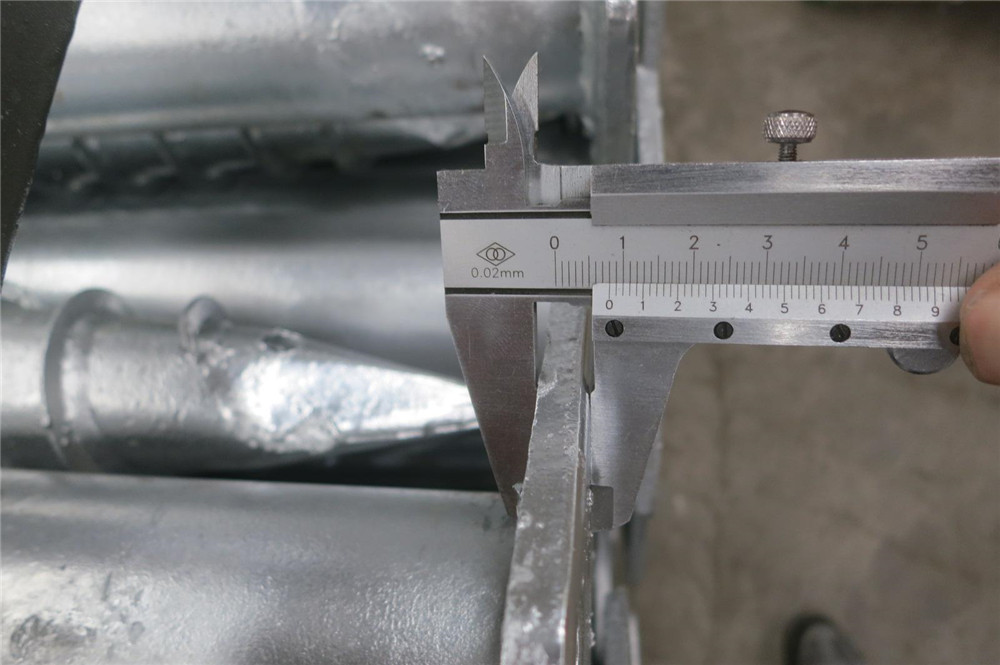

| Out Pipe Dia | 76MM |

| Pipe Thickness | 3MM |

| Weight | 5.2KG |

| Material | ISO630 Fe A / Din EN10025 Fe 360 B |

| Surface Finished | Hot Dipped Galv. As standard DIN EN ISO 1461-1999 |

| Delivery Time | 25 days after get 30% prepayment |

| Payment | L/C, T/T, D/P |

| MOQ | 360 pcs |

| Port | Xingang |

| Payment Term | 30% prepayment, the balance at sight B/L copy. |

| Package | 120pcs/pallet 3360pcs/20`container |

Product Process

Step 1: Cutting

The length of welded pipe is 6 meters and the welded pipe need to be cut by sawing machine according to customer's need.

Step 2: Heating

Putting ground screw to high frequency heating machine and make ground screw be soft so that ground screw can be shaping.

Step 3: Shrinking

Using shrinkage machine to change the shape and diameter of ground screw.

Step 4: Punching

Using punching machine to do a hole or other for ground screw.

Step 5: Welding

The spiral blade of ground screw will be welded by automatic welding machine.

Step 6: Galvanizing

The surface treatment is acid picking and hot dip galvanizing.

Step 7: Testing

Our quality control will test the goods and supply checking reports according to customer's need.

Step 8: Packing

Steel pallet is used to place ground screw and then wrap the pallet with multi-layer packaging to firm the ground screw.

Our Service

Pre-sale service

1. Sample can be offered with sample charge and delivery fee by buyer's side;

2. We have full stock and delivery them in short time;

3. OEM and ODM order are accepted and kinds of logo printing or design is available;

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying our best to offer you;

5. We have abundant experience about exporting and producing because we produce and export ground screw pile for more than 15 years.

After you choose

1. We will choose the cheapest shipping cost and make invoice once you want to take sample from us;

2. Checking quality again then send you at 2-5 working days after your payment;

3. Sending you the tracking number by email and chasing the parcels until it arrive you;

After-sale service

1. We will are very glad to receive your any idea about our production.

2. Any question about us,please contact us by E-mail or telephone.

Product Categories : Ground Screw > F Ground Screw